1 Department of Fashion Design, Footwear Design and Development Institute, Noida/Rae Bareli (Fusartganj Campus), Noida, Uttar Pradesh, India

Creative Commons Non Commercial CC BY-NC: This article is distributed under the terms of the Creative Commons Attribution-NonCommercial 4.0 License (http://www.creativecommons.org/licenses/by-nc/4.0/) which permits non-Commercial use, reproduction and distribution of the work without further permission provided the original work is attributed.

Every year, the fashion industry churns out millions of clothing items with fresh styles, resulting in significant fabric waste during production. This fabric waste contributes to environmental pollution. Embracing zero-waste pattern-making techniques for clothing production offers a viable solution to curbing this issue. By utilising the entire fabric yardage, these techniques aim to minimise or eliminate fabric waste after garment production. Zero-waste design is a holistic approach that integrates designing, production and sourcing processes. This article aims to propose solutions for controlling fabric waste through innovative zero-waste pattern-design techniques, thereby fostering a sustainable future. Traditionally, the apparel production process utilises 85% of fabrics, leaving behind 15% as wastage. The challenge lies in reducing this 15% wastage to zero (Abernathy et al., 1999). However, it is acknowledged that not everyone can readily adopt zero-waste pattern techniques. It requires creativity to develop optimal design solutions for apparel production. Collaboration among designers, pattern makers, academics and production professionals is essential for researching and identifying the best creative practices and solutions for integrating zero-waste pattern-making techniques into the apparel production process. Developing approaches for zero-waste pattern-making involves researching basic pattern design principles, understanding associated challenges and analysing outcomes. This research and development process in zero-waste pattern-making can pave the way for better sustainable practices, ultimately contributing to the reduction of fabric waste pollution and fostering a more sustainable future.

Zero waste, sustainable fashion, pattern cutting, design, techniques

Introduction

Zero-waste pattern-making plays a significant role in reducing waste and pollution in the fashion industry. Traditionally, garment production generates a significant amount of waste during the cutting process, where excess fabric is discarded as scraps. This results in a tremendous environmental impact due to the high consumption of resources, energy and water required to produce textiles.

The term zero-waste was introduced in the fashion sector by Fletcher for the circular economy approach.

Zero-waste pattern-making approaches aim to eliminate or minimise this waste by utilising fabric in a more efficient manner. Instead of relying on the conventional practice of creating patterns that leave unusable scraps, zero-waste patterns are designed to utilise every inch of fabric, leaving little to no waste.

Objectives

This article aims to provide solutions and develop techniques and methods to control textile material waste (Abernathy et al., 1999).

By adopting zero-waste pattern-making techniques, the fashion industry can achieve various benefits:

Waste reduction: Zero-waste patterns significantly reduce the amount of fabric waste generated during production. In addition to conserving resources, this approach also mitigates the necessity for disposal, thereby diminishing environmental pollution.

Resource conservation: As zero-waste patterns maximise fabric utilisation, less fabric needs to be produced for each garment. This reduces the overall demand for raw materials and conserves water, energy and other resources required for textile production.

Reduced carbon footprint: With less fabric waste, the carbon footprint associated with the disposal of textile waste is significantly decreased. Additionally, by reducing the need for new fabric production, the carbon emissions caused by manufacturing processes are also reduced.

Design innovation: Zero-waste pattern-making encourages designers to think creatively and develop innovative cutting techniques and garment constructions. This fosters unique and stylish designs that challenge the conventional approach to fashion.

Consumer perception: As environmental concerns become increasingly important to consumers, adopting zero-waste practices can enhance a brand’s reputation as socially and environmentally responsible. It can attract conscious consumers who prioritise sustainable choices and contribute to building a positive brand image.

Literature Review

Clothing and textiles industry is the second most polluted among industries around the world. It produces almost 20% wastewater and 85% landfill with textiles end wastage, this wastage can be reused to preserve our natural resources and environment. In this regard, zero-waste pattern-making can be one good approach. Most of apparel brands give more focus on design aesthetics, cost and production processes neglecting the impact of waste textile material on environment; however, consumers are becoming more concerned for eco-friendly products is a challenge. By considering the zero-waste pattern-making process, challenges can be resolved to a major extent by utilising the fabric fully or utilising the waste material to create new pattern designs for the development of new products. This zero-waste technique includes garment style, fabric, fabric width, silhouette, construction details, pattern-cutting layout, pattern piece adjustment and finishing details. Utilising the excess/waste fabric out of one pattern for another pattern or product development is another approach of zero-waste pattern-making as it complies to zero waste (Carrico & Kim, 2014).

To effectively implement zero-waste pattern-making, collaboration is crucial among designers, manufacturers and suppliers. It requires a shift in production practices, training and research to refine techniques and develop new solutions that align with sustainable fashion goals.

By embracing zero-waste pattern-making, the fashion industry takes a vital step towards reducing waste and pollution, promoting more sustainable practices and contributing to a greener future (Saeidi et al., 2018).

The Environmental Footprint of Fast Fashion

Every second, the fashion industry discards or incinerates the equivalent of one garbage truck’s worth of clothing.

Waste Control Methods

Various strategies exist for managing textile waste in the fashion industry:

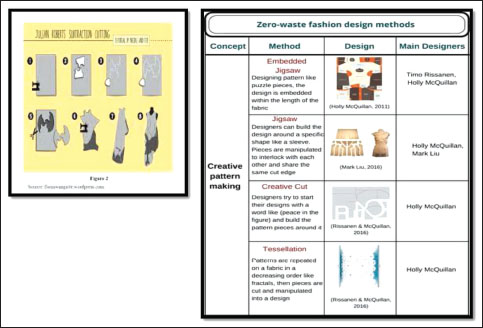

Zero-waste Pattern-development Techniques

There are some techniques to zero-waste pattern-design development (Carrico & Kim, 2014). mentioned below.

This article is result of research about the zero-waste pattern-making and adopting zero-waste pattern-making practices to control waste of textile materials. Information is gathered from the literature study and data collected from books, the internet and research practitioners. The practice-based research methods are also used to obtain the knowledge about practices used to control waste. Data collection from literature study and practice-based research about zero-waste practices, it is observed that most of practitioners are utilising one fabric into one garment. Some are efficiently planning layout plans for different pattern components to minimise the waste (Townsend & Mills, 2013).

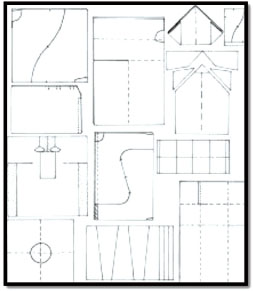

Some of manufacturing units have initiated zero-waste pattern-making techniques to create garment and scrap fabric is also used for another pattern development (Figures 1 to 6).

Figure 1. Zero-waste Cutting by Holly McQuillan.

Figure 2. Pattern Construction Plan.

Source: Carrico and Kim (2014).

Figure 3. Jigsaw Method.

Source: El Shishtawy et al. (2021).

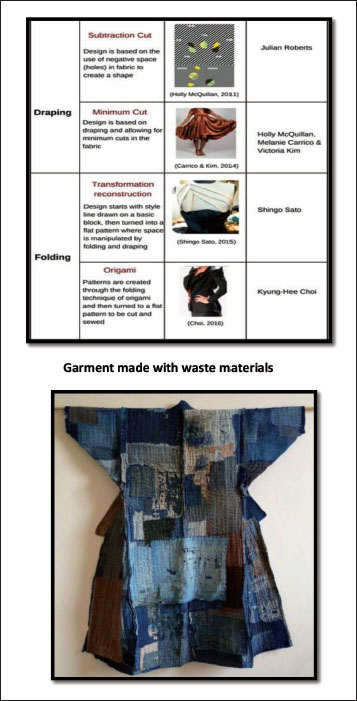

Figure 4. Boro and Others Japanese Recycled Wonder.

Figure 5. Apparel Made from Waste Textile Material.

Source: Development by Purvi Mittal (2023) FD Alumni FDDI, Rae Bareli.

Figure 6. Raw Waste Textile Material.

Source: Development by Purvi Mittal (2023) FD Alumni FDDI, Rae Bareli.

Conclusion

Society is becoming more aware about environmental issue. As the sustainable fashion issue is prime agenda for sustainable development, zero-waste pattern-making can solve the issue of textile waste dumping landfills. Collaboration among academicians, designer, researchers, manufacturers and technologists can solve the challenge of waste control management and preserving the environment. At the present scenario, the study of zero-waste pattern-making technique is still in a nascent stage. Adopting zero-waste pattern-making needs precise planning in methods and techniques to work out the best solution considering design, aesthetics and waste control. The practices adopted during research have observed that it can solve the problem of textile waste control. Zero-waste pattern-making approach can provide a solution for economic and ecological challenges of waste dumping. The adoption of zero-waste pattern-making holds promise for enhancing sustainable practices and managing textile waste pollution more effectively in the future (Niinimäki, 2011).

Declaration of Conflicting Interests

The authors declared no potential conflicts of interest with respect to the research, authorship and/or publication of this article.

Funding

The authors received no financial support for the research, authorship and/or publication of this article.

Abernathy, F. H., Dunlop, J. T., Hammon, J. H., & Weil, D. (1999). A stitch in time: Lean retailing and the transformation of manufacturing—Lessons from the apparel and textile industries. Oxford University Press.

Carrico, M., & Kim, V. (2014). Expanding zero-waste design practices: A discussion paper. International Journal of Fashion Design, Technology and Education, 7(1), 58–64. https://doi.org/10.1080/17543266.2013.837967

El Shishtawy, N., Sinha, P., & Bennell, J. A. (2021). A comparative review of zero-waste fashion design thinking and operational research on cutting and packing optimisation. International Journal of Fashion Design, Technology and Education, 15(2), 187–199. https://doi.org/10.1080/17543266.2021.1990416

Ellen MacArthur Foundation. (2017). A new textiles economy: Redesigning fashion’s future. Retrieved, 20 March 2020, from https://www.ellenmacarthurfoundation.org/publications

McQuillan, H. (2011). Zero-waste design practice: Strategies and risk taking for garment design. In A. Gwilt & T. Rissanen (Eds.), Shaping sustainable fashion: Changing the way we make and use clothes (pp. 83–97). Earthscan.

Niinimäki, K. (2011). From disposable to sustainable: The complex interplay between design and consumption of textiles and clothing [PhD dissertation, Aalto University].

Roberts, J. (2008). Subtraction cutting school. Center for Pattern Design.

Saeidi, E., & Wimberley, V. S. (2018). Precious cut: Exploring creative pattern cutting and draping for zero-waste design. International Journal of Fashion Design, Technology and Education, 11(2), 243–253. https://doi.org/10.1080/17543266.2017.1389997

Townsend, K., & Mills, F. (2013). Mastering zero: How the pursuit of less waste leads to more creative pattern cutting. International Journal of Fashion Design, Technology and Education, 6(2), 104–111. https://doi.org/10.1080/17543266.2013.793746

Web References

https://fairtradefinder.com/blog/clothes-made-from-recycled-materials/

https://www.cooperhewitt.org(/2016/10/25)boro-and-other-japanese-recycled-wonders.

https://dr.lib.iastate.edu/server/api/core/bitstreams/6c9cec2e-af45-4458-ab94-315bc5c7aafe/content

https://eprints.whiterose.ac.uk/179239/13/A%20comparative

https://www.scribd.com/document/561514410/Fashion-Creativity-in-Zero-Waste-

Pattern-Making

https://fairtradefinder.com/blog/clothes-made-from-recycled-materials/

https://www.genevaenvironmentnetwork.org/resources/updates/sustainable-fashion/

https://isitleather.com/blog/the-sustainability-of-leather-fashion-over-fast-fashion-trends/