1Department of Management Studies, Madurai Kamaraj University, Madurai, Tamil Nadu, India

2Department of Business Administration, Thiagarajar College, Madurai, Tamil Nadu, India

Creative Commons Non Commercial CC BY-NC: This article is distributed under the terms of the Creative Commons Attribution-NonCommercial 4.0 License (http://www.creativecommons.org/licenses/by-nc/4.0/) which permits non-Commercial use, reproduction and distribution of the work without further permission provided the original work is attributed.

This article offers a thorough review of the literature on product- and service-based supply chain (SC)-based capacity management (CM) solutions for the services industry. The primary objective is to address the research deficit concerning CM within SC operations, particularly given the escalating trend of SCs integrating service provision. The study aims to delineate the foundational principles and methodical approaches required for efficient capacity increase by synthesising knowledge across the disciplines of operations management, manufacturing SCs, services marketing and industrial engineering. The analysis indicates that CM is frequently underrepresented in SC literature, particularly as it relates to the burgeoning service economy. Crucially, research gaps exist concerning the evolving network-based SC systems prevalent in underdeveloped economies. The study affirms that building capacity, defined as enhancing the knowledge, skills and expertise of individuals and organisations, is critical for modern SC management (SCM). Effective capacity expansion is essential for improving operational efficiency, reducing costs, and providing customer value amidst intensified globalisation and technological change. This research proposes a value delivery technique utilising capacity management systems (CMSs) to effectively mitigate SC risks (SCRs) and enhance overall business performance.

The increasing proportion of consumer spending allocated to services has underscored their growing significance, leading to the assertion that services are relevant across all business sectors.

Supply chain, capacity management strategies, supply chain risk management (SCRM), services supply chains (SSC), capacity augmentation, value delivery frameworkts7

Introduction

Enhanced supply chain (SC) performance is positively correlated with greater resilience to risk, and the mitigation of process and demand risk directly impacts SC performance. The SC literature frequently categorises its focus into three main areas: managing ‘capacity’, managing ‘demand’ and SC collaboration.

Specifically, the relationship between SC risks (SCRs) and organisational agility is mediated by the reconfiguration of resource capacity (Ambulkar et al., 2015). A deficit in SC capacity impedes service provision, and end-user flexibility is consequently influenced by sourcing flexibility and flexible capacity. Moreover, organisational flexibility demonstrates a positive association with just-in-time (JIT) procedures (Youssef et al., 2015). Effective management of SC flexibility can ultimately enhance overall organisational performance.

Capacity Investment and Capacity Management Systems (CMSs)

Although it may appear counterintuitive, competing service providers may strategically advantage by investing in service capacity ahead of projected demand. They are highly motivated if these capacity investments lead to increased demand and the preservation of market share. Managing demand variation requires the application of CM strategies. An evaluation of the structural features and language employed in earlier studies indicates that CM alternatives, rather than CMSs, dominate the topic.

Study Objectives and Contribution

This work aims to give a comprehensive overview of evolving strategies in capacity planning and the application of CMSs. This is achieved through the following specific objectives:

As a foundational study, this research offers a solid basis for subsequent empirical investigations and the assessment of the impact of CMS on business performance. This review is highly relevant for both academic researchers and SC management (SCM) professionals across the manufacturing and service sectors, and effectively bridges the divide between theoretical research and contemporary operational practice.

Review Methodology

Research Questions (RQs) and Methodology

This study was designed to address the following five primary RQs concerning the application of CM within SC operations:

Review Methodology

To provide clarity regarding the search and evaluation procedures specific to this field, a literature review methodology was employed. This approach is grounded in the foundational review frameworks established for analysing CM research.

The overall review process comprised two main phases:

Stage 1 of the procedure is detailed in Review Methodology, which covers the data extraction process, the analysis framework utilised, and the established search criteria and selection procedure.

Manuscript Search and Selection Methodology

The search and selection procedure were conducted in four sequential steps.

In Stage 1, a total of 6,328 items published between 1980 and 2025 were identified. This initial identification was performed using keyword searches in selected online catalogues, which were chosen based on their repository relevance and depth.

Subsequently, in Stage 2, the co-authors screened and reviewed 664 manuscripts based on an analysis of their abstracts and article contents. Stage 3 involved a further refinement, where 565 articles remained after the elimination of those that exclusively addressed service quality within a business-to-consumer (B2C) context.

The final selection, Stage 4, yielded 133 publications from peer-reviewed journals. This selection was based on the articles’ research contributions to the study’s theme, focusing on: the applicability of product-related research findings to the realms of services, post-sale support and general service scholarship. A key observation was that the majority of these publications originated from the fields of production, operations, logistics and transportation management within the broader SC discipline, rather than specifically from SC systems literature.

Role and Benefits of CM in SCs

The implementation of CM within SCs is intrinsically linked to two primary areas:

Three distinct advantages are derived from the application of CM.

Core Advantages of CM

CM, especially within SCs, provides the following key benefits:

Effective capacity planning ensures an optimal balance between resource utilisation and demand. This leads to:

By aligning current resources with forecasted demand, CM streamlines operations:

A well-managed capacity allows a business to consistently meet customer expectations:

Analysis Framework

This section describes the structured analytical framework developed for the systematic review of the literature, employed to address the study’s RQs (RQ1–RQ5).

Analytical Framework Design

To systematically assess the literature and answer the exploration questions, a detailed analytical framework was constructed. The review proceeded by chronologically recapitulating the research progression within the literature and conducting cross-categorical analyses.

The Framework Utilised Several Distinct Ordering Criteria for Analysis

Positional and Categorical Coding

Research Methodology (RM)

To understand the evolution of research approaches, studies were coded according to their primary RM.

Furthermore, geographic region codes were applied, or author location codes for region-independent studies. The designation Americas encompassed the North, South and Central USA. The code transcontinental (Tc) was assigned to studies that spanned multiple distinct geographic divisions, allowing for an examination of the compiled study’s geographic region and its dominant methodological approaches.

Data Extraction

Data Extraction and Coding

To establish a comprehensive record of the decision-making process and create a data repository, established data extraction forms recommended by Tranfield et al. (2003) for systematic literature analysis were employed. The primary fields coded during the extraction process included the major subject, sub-themes, critical issues, key terminology, level of analysis (LOA), EOEs, RM and geographical region.

Scope and Thematic Focus

This literature overview concentrates on two overarching themes:

The CMSs value delivery methodology considers three distinct relationships between CMS implementation and overall business performance.

Classification and Reliability Measures

Thematic Categorisation and Consensus

The collected research was categorised and classified independently by each co-author. Any resulting disagreements were resolved through an iterative process that involved discussions, the potential addition of new themes or issues, and/or subsequent reclassification. Different themes, along with their associated sub-themes and specific issues, are detailed in Strategies for CM.

Each article was coded using binary indicators (‘Y’, ‘N’ or ‘covered’/‘not covered’) to denote the presence of the theme or sub-theme. The complete coding scheme for the identified themes and sub-themes across the selected studies is presented in the Annexure.

Inter-author Reliability and Validity

A three-decade span of literature was examined to ensure the dependability of the review. To mitigate bias of the author, peer review among the authors was conducted at every critical stage, including the search and selection, framework development and data extraction processes. The use of an iterative content analysis procedure combined with disagreement resolution through peer review and discussion ensured inter-author trustworthiness.

Outline of the Remaining Sections

This framework was used for the RQs in the following phase of the literature review.

Background Research and Theory Development

The terminology utilised, as well as the main themes, business procedures and important issues examined in the application of CMSs, are analysed in this section. This analysis focuses on RQ1 (themes) and RQ2 (terminologies) in the subsections under "Strategies for CM."

Encompassing of Studies Under Various Terms and Conditions

Academic Classification of SC Capacity Research

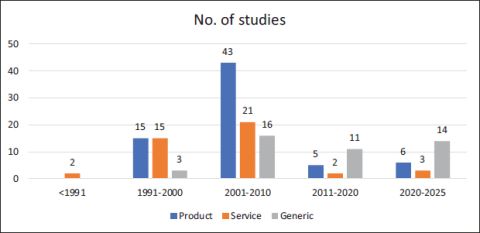

This passage classifies the existing body of SC research into three categories based on their primary focus regarding capacity and service provision (Figure 1).

This category focuses on conventional manufacturing SCs and the operational challenges inherent in producing tangible goods.

Figure 1. Terminologies Evolution on Capacity Management Strategies in Supply Chains.

This category addresses the unique dynamics and complexities of service delivery, where production and consumption are simultaneous.

This third, integrative category combines aspects of both product and service domains, focusing on network-level operations.

SC Hazards

This passage underscores the heightened scholarly attention directed towards SCRs, particularly focusing on the interrelated hazards of service delivery integrity, capacity constraints and demand volatility. It synthesises key academic perspectives regarding the detrimental consequences of these hazards and outlines established mitigation approaches.

Core SCRs and Consequences

Academic literature identifies significant risks associated with operational variance and capacity limitations:

Risk Mitigation and Visibility Enhancement

Research suggests that collaborative and informational strategies are pivotal in addressing these hazards:

In conclusion, effective SC risk management requires a dual focus on minimising both the negative impacts of demand volatility and the operational inefficiencies resulting from capacity imbalances, leveraging both inter-organisational cooperation and enhanced visibility.

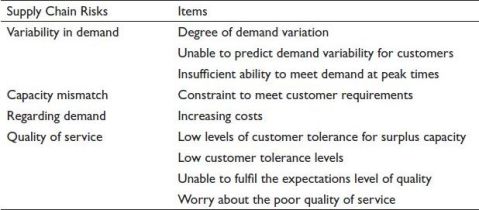

Crucial SCRs are included in Table 1.

Strategies for CM

Capacity Planning and Information Sharing

‘When the lead time for replenishing was less than the seasonal period, information sharing led to better performance’. ‘To improve SC effectiveness, organizations must actively acquire information’ (Afolayan et al., 2016).

Table 1. Key Supply Chain Risks Identified from Selected Studies.

‘The effectiveness of knowledge management (KM), R&D innovation, and business performance are all significantly impacted by KM enablers’ (Kamath et al., 2016).

‘Knowledge sharing is positively impacted by organizational culture, and this in turn improves organizational agility’.

Increasing Capacity to Manage Spikes in Demand During Peak

‘Variables related to people excellence have a favourable impact on organizational maturity, which results in business outcomes for employees, the company, and customers’ (Kothandaraman & Kamalanabhan, 2018).

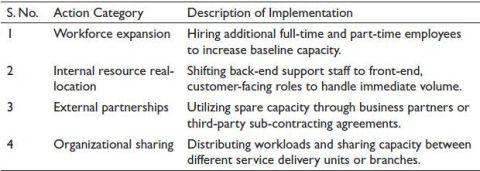

‘Changes in staffing, hiring more full-time employees, adding part-time employees, shifting back-end to front-end staffing, keeping temporary/extra staff using spare capacity with business partners (sub-contract work out), and/or sharing capacity between various service delivery organization parts are some of the key capacity augmentation actions during peaks’ (Table 2).

Increasing Capacity Amid Brief Spikes in Demand

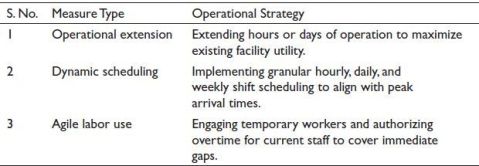

‘Increased hours/days of operation, hourly/daily scheduling, weekly/shift staff scheduling, hiring temporary workers, and scheduling overtime for specific staff are examples of capacity augmentation measures during brief demand spikes’ (Table 3) (Zeithaml et al., 1985).

Table 2. Key Capacity Augmentation Actions During Peaks..

Table 3. Capacity Augmentation Measures During Brief Demand Spikes.

Strategies to Make Use of Available Capacity During Lean Periods

‘Because services are ephemeral, a company’s capacity should be intelligently allocated from both an operational and marketing standpoint in order to boost performance’ (Brausch & Taylor, 1997).

‘Lean times have a detrimental effect on financial performance and result in low-capacity utilization. Training employees and partners’.

Results of CMS Implementation

‘Prioritizing the SC coordination mechanism is aided by the relationship between cost, flexibility, quality, service level, and lead time’. ‘Businesses can use integrated world-class supply chain management techniques to address quality-cost-time trade-offs’. ‘Financial performance, adaptability, dependability, and quality are all components of economic sustainability’ Key findings: Key result of the SC (77) (Figure 2).

Examination of the Reviewed Material and Conversations

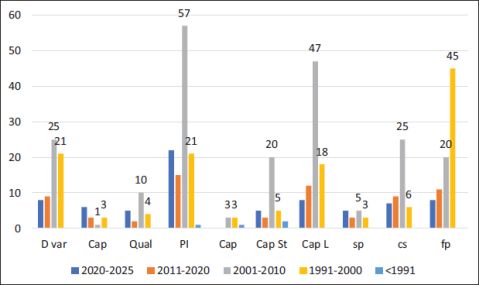

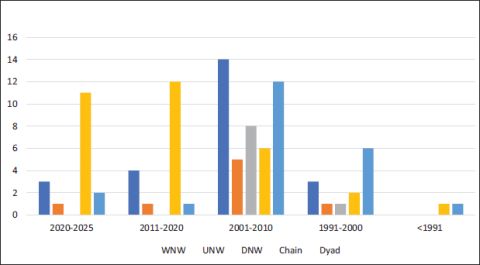

The research development in the structural dimensions (LOA and EOEs) is presented in this section. The RQs RQ1 and RQ2 are addressed by this cross-category study.

Reports Concerning the LOA

Figure 3 demonstrates the research study on CM strategies in the structural dimension. Since the 1990s, the term ‘product’ has dominated studies, particularly in the context of ‘chains’. Only in DNW and WNW, which deal with SC and networks associated with outbound logistics, did services surpass products. Research on DNWs has grown between 2001 and 2010, and this growth is linked to an increase in logistics management.

Figure 2. Number of Studies Against Each Theme.

Figure 3. Research Study on Capacity Management Strategies on Structural Dimension.

Reports from All EOEs

The majority of studies discuss the exchange of assets and information as a crucial component of exchanges. Asset exchange is essential for even service-oriented enterprises, such as retail, food services, rentals, hotels and hospitality, hospitals and health services, and logistics and distribution. Information exchange is essential to any transaction in light of information technology (IT) improvements. Information and relationship components have been the subject of studies on ‘capacity planning and information sharing’. Since 2001, there has been an emphasis on knowledge and relationship exchanges. There are a few studies that address the knowledge dimension. Product manufacturing studies tend to focus more on information and assets than on relationships and knowledge. The growing emphasis on relationships and knowledge components has been sparked by the work being done in services and SC networks.

Figure 4. Geographical Scope of Research.

Collaboration, cooperative planning and knowledge exchange are now necessary as a result of increased outsourcing.

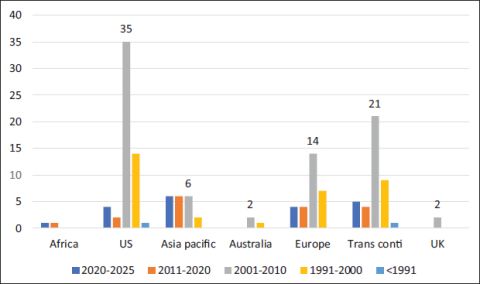

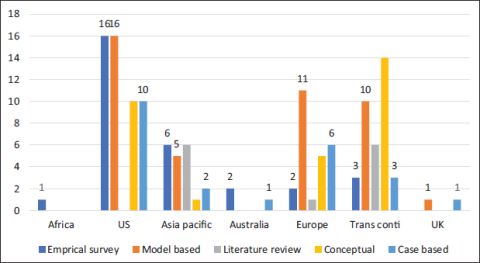

Research Advancements by Regions and Research Approaches (Figure 4)

The major regions with the greatest amount of CMS investigations have been the Americas, Asia and Europe (Figure 5). Conceptual research comes in second, after model-based and empirical studies. Research conducted in the Americas shows that the economy is increasing and that SC efforts are becoming more and more popular, particularly in the manufacturing of products. The transcontinental study, in contrast to the Americas, focuses on conceptual studies that have examined strategies for handling demand unpredictability.

Comparing Research Across Significant Themes Across Continents

All of the main scientific topics are represented by the Americas. The majority of research in the Americas focuses on using capacity planning and information exchange to address the problem of demand fluctuation. Research has concentrated more on challenges across the areas.

Figure 5. Geographical Study Against Research Methods.

Studies that span several geographies are referred to as transcontinental studies, as are conceptual and modelling studies that have regional applicability and were started in any geography.

Focus on Findings and Solutions

Following initial CM models, empirical and case-based studies validated the results, ultimately leading to the proposal of a value delivery framework aimed at mitigating SCRs (like demand fluctuation and delivery issues) and enhancing overall performance (Figure 6).

Focus on Business Benefit

Companies that strategically differentiate their capacity usage, especially during lean economic periods, achieve better capital utilisation and higher returns on investment.

In order to increase capacity utilisation, there is a rising focus on alternative uses of capacity during lean times, even if the primary priorities are capacity planning, information exchange and long- and short-term capacity augmentation. In addition to cutting workers as a short-term solution, progressive businesses use lean periods to manage non-urgent activities, train staff and partner resources, and increase interaction in providing the best customer touchpoints. Additionally, they provide interaction as an alternative to automated or self-service procedures. Among the most significant advantages that a CMS offers are improved SC performance, customer happiness and financial outcomes.

Figure 6. Capacity Management Strategies.

Conclusions

This chapter summarises distinctive submissions, limitations and future research opportunities derived from the study, based on the findings related to its RQs.

Unique Contributions of the Article

The article makes several unique contributions to the CM literature, primarily by addressing identified research gaps:

Findings Based on RQs

The article’s findings, discussed in Sections 3 and 4 (relating to RQ1 and RQ2), establish the current state and advancement of research regarding SCRs and CMS utilisation:

Determining Potential Research Gaps and Scope

Current academic literature reveals a fragmentation in CM research, with a disproportionate focus on SCM within the manufacturing sector. Research concerning service supply chains (SSCs) is largely tangential, often concentrating on the downstream activities of manufactured goods, such as distribution, logistics or post-purchase services, leaving SCM in pure service contexts under-addressed.

A significant methodological limitation is the prevailing focus on linear ‘chains’ rather than complex ‘networks’, particularly in the downstream sphere. Furthermore, empirical investigation into the value proposition of CM organisations (CMOs) and demand management organisations (DMOs) has been scarce since the foundational work of Klassen and Rohleder (2010). Similarly, studies that conceptualise ‘knowledge’ as a key exchange component within SC interactions remain rare.

Conceptual Contribution and Empirical Directives

This study introduces a novel conceptual framework designed to guide subsequent empirical research on CMSs. We advocate for a strategic managerial emphasis on the CMS across the entire service lifecycle. Assessing the utility of the CMS necessitates a holistic evaluation of the interdependencies between intra- and inter-structural elements of the SC.

We recommend the integration of the CMS throughout the entire SC, including upstream tiers and DNWs. The CMS should be leveraged for capacity planning and scheduling simulations, facilitating a seamless, reciprocal flow of information between planning and service delivery. A critical strategic imperative is to focus on knowledge exchange within SCs to effectively mitigate SCRs.

Future Research Trajectories

Future research should focus on clarifying the intricate linkages between the client, service provider, marketing, design and manufacturing functions. Addressing the scarcity of studies on knowledge exchange can be achieved by empirically investigating the structural formation of DNWs (e.g., clusters for back-office operations, online sales/pricing, logistics and customer support). Such studies would enhance comprehension of the evolving configuration—specifically, stakeholder identification, requirements and relationship dynamics.

To advance global competencies, particularly in relation to the CMS, we urge intensified empirical investigation and comparative analysis across diverse geopolitical regions, including Asia, Australia, Europe, the UK and Africa. The CMS must be institutionally embraced across these regions to precisely determine the value derived from its implementation. This necessitates transcontinental research to examine the global, regional and local practices associated with CMS deployment, the structural variables of the SC system, and to provide cross-industry comparisons alongside a focus on specific industry practices.

Declaration of Conflicting Interests

The authors declared no potential conflicts of interest with respect to the research, authorship and/or publication of this article.

Funding

The authors received no financial support for the research, authorship and/or publication of this article.

ORCID iD

A. Maragathamuthu  https://orcid.org/0000-0003-1159-074X

https://orcid.org/0000-0003-1159-074X

Afolayan, A., White, G. R. T., & Mason-Jones, R. (2016). Why knowledge acquisition is important to effective supply chain management: The role of supply chain managers as knowledge acquisitors. British Academy of Management Conference, Newcastle.

Agarwal, A., Shankar, R., & Tiwari, M. K. (2006). Production, manufacturing and logistics modelling the metrics of lean, agile and legal supply chain: An ANP-based approach. European Journal of Operational Research, 173(1), 211–225.

Agrawal, A. K., Kumar, D., & Rahman, Z. (2017). An ISM approach for modelling the enablers of sustainability in market-oriented firm. International Journal of Business Excellence, 12(1), 23–45.

Ambulkar, S., Blackhurst, J., & Grawe, S. (2015, January). Firm’s resilience to supply chain disruptions: Scale development and empirical examination. Journal of Operations Management, 33(2), 111–122.

Andersen, E. G., & Morris, D. J. (2000). A simulation game for service-oriented SCM: Does information sharing managers with service capacity decisions? The Journal of Production and Operations Management, 9(1), 40–55.

Anderson, E. G., Jr., Fine, C. H., Gilboy, G. J., & Parker, G. G. (1995). Upstream volatility in the supply chain: The machine tool industry as a case study. Production and Operations Management, 9(3), 239–261.

Ang, S., & Straub, D. W. (1998). Production and transaction economies and is outsourcing: A study of the US banking industry. MIS Quarterly, 22(4), 535–552.

Auramo, J., & Ala-risku, T. (2005). Challenges for going downstream. International Journal of Logistics Research and Applications, 8(4), 333–345.

Avery, S. L., & Swafford, P. M. (2009). Social capital impact on service supply chains. Journal of Service Science, 2(2), 9–16.

Bai, L., Liu, H., Tsui, K. L., & Ye, H. Q. (2008). Reducing bullwhip effect in supply chains using control variates. Quality Technology & Quantitative Management, 5(3), 221–241.

Baramichai, M., Zimmers, E. W., Jr., & Marangos, C. A. (2007). Agile supply chain transformation matrix: An integrated tool for creating an agile enterprise. Supply Chain Management: An International Journal, 12(5), 334–348.

Barve, A. (2010). Impact of supply chains agility on customer satisfaction. International Conference on E-business, Management and Economics.

Bhattacharya, R., & Bandyopadhyay, S. (2011). A review of the causes of bullwhip effect in a supply chain. International Journal of Advanced manufacturing Technology, 54(9), 1245–1261.

Bolumole, Y. A. (2003). Evaluating the supply chain role of logistics service providers. The International Journal of Logistics Management, 14(2), 93–107.

Boone, T., & Ganeshan, R. (2001). The effect of information technology on learning in professional service organizations. Journal of Operations Management, 19(4), 485–495.

Boukherroub, T., Ruiz, A., Guinet, A., & Fondrevelle, J. (2015, February). An integrated approach for sustainable supply chain planning. Computers & Operations Research, 54(2), 180–194.

Brausch, J. M., & Taylor, T. C. (1997). Who is accounting for the cost of capacity. Management Accounting, 44–50.

Bray, R. L., & Mendelson, H. (2012). Information transmission and the bullwhip effect: An empirical investigation. Management Science, 58(5), 860–875.

Buchmeister, P., & Palcic, P. (2008). Bullwhip effect problem in supply chains. Advances in Production Engineering and Management, 3(1), 45–55.

Butner, K. (2010). The smarter supply chain of the future. Strategy & Leadership, 38(1), 22–31.

Cachon, G. P., & Fisher, M. (2000). Supply chain inventory management and the value of shared information. Management Science, 46(8), 1032–1048.

Cachon, G. P., & Lariviere, M. A. (1999). Capacity choice and allocation: Strategic behaviour and supply chain performance. Management Science, 45(8), 1091–1108.

Cachon, G. P., Taylor, R., & Schmidt, G. M. (2007). In search of the bullwhip effect. Manufacturing and Service Operations Management, 9(4), 457–479.

Caridi, M., Crippa, L., Perego, A., Sianesi, A., & Tumino, A. (2010). Measuring visibility to improve supply chain performance: A quantitative approach. Benchmarking: An International Journal, 17(4), 593–615.

Carlsson, C., & Fuller, R. (2000). A fuzzy approach to the bullwhip effect. Conference Proceedings: 15th European Meet, Cybernetics and Systems Research (pp. 228–233).

Croom, S., Romano, P., & Giannakis, M. (2000). Supply chain management: An analytical framework for critical literature review. European Journal of Purchasing & Supply Management, 6(1), 67–83. https://doi.org/10.1016/S0969-7012(99)00030-1

Disney, S. M., & Towill, D. R. (2003b). Vendor-managed inventory and bullwhip reduction in a two-level supply chain. International Journal of Operations & Production Management, 23(6), 568–595.

Frohlich, M. T., & Westbrook, R. (2001). Arcs of integration—An international study of supply chain strategies. Journal of Operations Management, 19(2), 185–200.

Frohlich, M. T., & Westbrook, R. (2002). Demand chain management in manufacturing and services: Web-based integration, drivers and performance. Journal of Operations Management, 20(1), 729–745.

Gravier, M. J., & Farris, M. T. (2008). An analysis of logistics pedagogical literature: Past and future trends in curriculum, content, and pedagogy. The International Journal of Logistics Management, 19(2), 233–253.

Gunasekaran, A., Lai, K. H., & Cheng, T. C. E. (2008). Responsive supply chain—A competitive strategy in networked economy. Omega, 36(1), 549–564.

Gunasekaran, A., & Ngai, E. W. T. (2005). Build-to-order supply chain management: A literature review and framework for development. Journal of Operations Management, 23(5), 423–451.

Guo, X., Ling, L., Dong, Y., & Liang, L. (2013, April). Cooperation contract in tourism supply chains: The optimal pricing strategy of hotels for cooperative third-party strategic websites. Annals of Tourism Research, 41(2), 20–41.

Holmström, J., Pertu, L., Antti, V., & William, H. (2001). The other end of the supply chain. Supply Chain Forum: An International Journal, 2(1), 22–25.

Holweg, M., & Bicheno, J. (2002). Supply chain simulation—A tool for education, enhancement and endeavour. International Journal of Production Economics, 78(2), 163–175.

Hope, C., & Mühlemann, A. (1997). Service operations management: Strategy, design, and delivery. Prentice Hall.

Hübner, A. H., Kuhn, H., & Sternbeck, M. G. (2011). Demand and supply chain planning in grocery retail: An operations planning framework. International Journal of Retail and Distribution Management, 41(7), 512–530.

Jallat, F., & Ancarani, F. (2008). Yield management, dynamic pricing and CRM in telecommunications. Journal of Services Marketing, 22(6), 465–478.

Johnston, R. (2005). UPDATE: Service operations management: From the roots up. International Journal of Operations & Production Management, 25(12), 1298–1308.

Kaipia, R., Korhonen, H., & Hartiala, H. (2006). Planning nervousness in a demand supply network: An empirical study. The International Journal of Logistics Management, 17(1), 95–113.

Kamath, V., Rodrigues, L. L. R., & Desai, P. V. (2016). The significance of knowledge management, innovation on firm performance in the Indian manufacturing sectors: An empirical analysis. International Journal of Business Excellence, 9(2), 178–191.

Kandampully, J. (2000). Case study—The impact of demand fluctuation on the quality of service: A tourism industry example. Managing Service Quality, 10(1), 10–18.

Khan, M. Z., Kumar, A., Liu, Y., Gupta, P., & Sharma, D. (2024). Modelling enablers of agile and sustainable sourcing networks in a supply chain: A case of the plastic industry. Journal of Cleaner Production, 435, 140522. https://doi.org/10.1016/j.jclepro.2023.140522

Kim, H. J. (2017). The complementary effects of transaction cost economics and resource-based view: A technological alliance perspective. International Journal of Business Excellence, 13(3), 355–376.

Kim, H., & Bang, Y. (2025). Examining barriers and facilitators of capacity building in development: A systematic review of international development projects. Development Studies Research, 12(1). https://doi.org/10.1080/21665095.2025.2517766

Kok, T. D., Janssen, F., Doremalen, J. V., Wachem, E. V., Clerkx, M., & Peeters, W. (2005). Philips electronics synchronizes its supply chain to end the bullwhip effect. Interfaces, 35(1), 37–48.

Kothandaraman, K., & Kamalanabhan, T. J. (2018). People process excellence and business outcomes—A structural equation modelling-based analysis. International Journal of Business Excellence, 15(1), 1–17.

Lee, H. L. (2001). Ultimate enterprise value creation using demand-based management (Stanford Global Supply Chain Management Forum, SGSCMF-W1-2001). Stanford University.

Lee, H. L. (2002). Aligning supply chain strategies with product uncertainties. California Management Review, 44(3), 105–119.

Leech, D. P., Link, A. N., Scott, J. P., & Reed, L. S. (1998). TASC Inc.—The economics of a technology-focused services sector, a planning report for NIST.

Leishman, J., Robison, R., Rogers, C., & Zarbock, S. (2005). Bullwhip effect BUSM, 361, Sec 2. Bahria University.

Lim, D., & Palvia, P. (2001). EDI in strategic supply chain: Impact on customer service. International Journal of Information Management, 21(3), 193–211.

Liu, S., Moizer, J., Megicks, P., Kasturiratne, D., & Jayawickrama, U. (2014). A knowledge chain management framework to support integrated decisions in global supply chains. Production Planning & Control, 25(8), 639–649.

Lovelock, C. H. (1983). Classifying services to gain strategic marketing insights. Journal of Marketing, 47(3), 9–20.

More, E., & McGrath, M. (2002). An Australian case in e-health communication and change. Journal of Management Development, 21(8), 621–632.

Moreau, A. D. (1999). Waiting for service: Ten years of empirical research. International Journal of Service Industry Management, 10(2), 171–189.

Moyaux, T., Chaib-draa, B., & D’Amour, S. (2007). Information sharing as a coordination mechanism for reducing the bullwhip effect in a supply chain. IEEE Transactions on Systems, Man and Cybernetics—Part C: Applications and Reviews, 37, 396–409.

Murdick, R. G., Render, B., & Russell, R. S. (1990). Service operations management. Operations management series. Allyn and Bacon.

Rajani, R. L., & Heggde, G. S. (2020). Capacity management strategies in supply chains—A critical review and directions for future. International Journal of Business Excellence, 21(1), 81. https://doi.org/10.1504/ijbex.2020.106951

Tranfield, D., Denyer, D., & Smart, P. (2003). Towards a methodology for developing evidence-informed management knowledge by means of systematic review. British Journal of Management, 14(3), 207–222. https://doi.org/10.1111/1467-8551.00375

Vickery, S. K., Jayaram, J., Droge, C., & Calantone, R. (2003). The effects of an integrative supply chain strategy on customer service and financial performance: An analysis of direct versus indirect relationships. Journal of Operations Management, 21(5), 523–539.

Wang, Y., Wallace, S. W., Shen, B., & Choi, T. M. (2015). Service supply chain management: A review of operational models. European Journal of Operational Research, 247(3), 685–698.

Wu, D. Y., & Katok, E. (2006). Learning, communication, and the bullwhip effect. Journal of Operations Management, 24(6), 839–850.

Youssef, M. A., Youssef, E. M., & Motwani, J. G. (2015). A structural equation model for measuring the JIT intensity and its impact on manufacturing flexibility. International Journal of Business Excellence, 8(3), 324–356.

Yu, M. C., & Goh, M. (2014). A multi-objective approach to supply chain visibility and risk. European Journal of Operational Research, 233(1), 125–130.

Zeithaml, V. A., Parasuraman, A., & Berry, L. L. (1985). Problems and strategies in services marketing, Journal of Marketing, 49(2), 33–46.

Zhao, L., Huo, B., Sun, L., & Zhao, X. (2013). The impact of supply chain risk on supply chain integration. Supply Chain Management: An International Journal, 18(2), 115–131.

Annexure: Coding Scheme Summary

Themes: Supply Chain Risks (Demand Variability, Capacity Mismatch, Quality); CMS Strategies (Planning, Information Sharing, Augmentation); and Performance Results (Financial, Customer Satisfaction).